安全梯形刀片组

SKU #10524

Slice® 10524安全梯形刀片非常适合用在我们10490及10491金属柄安全美工刀上。10524安全梯形刀片使用先进陶瓷技术,拥有无火花、无磁性、具化学堕性、无需上油保养及不生锈等特性。Slice的刀片100%纯氧化锆陶瓷制作,并采用坚固且独特安全刀片设计,即便是切割强硬的材料,仍然表现出绝佳的耐磨性。事实上,Slice的安全刀片其使用寿命是钢制刀片的11倍。此外,其特殊的安全刀刃更有助于减少伤害,从而降低成本。

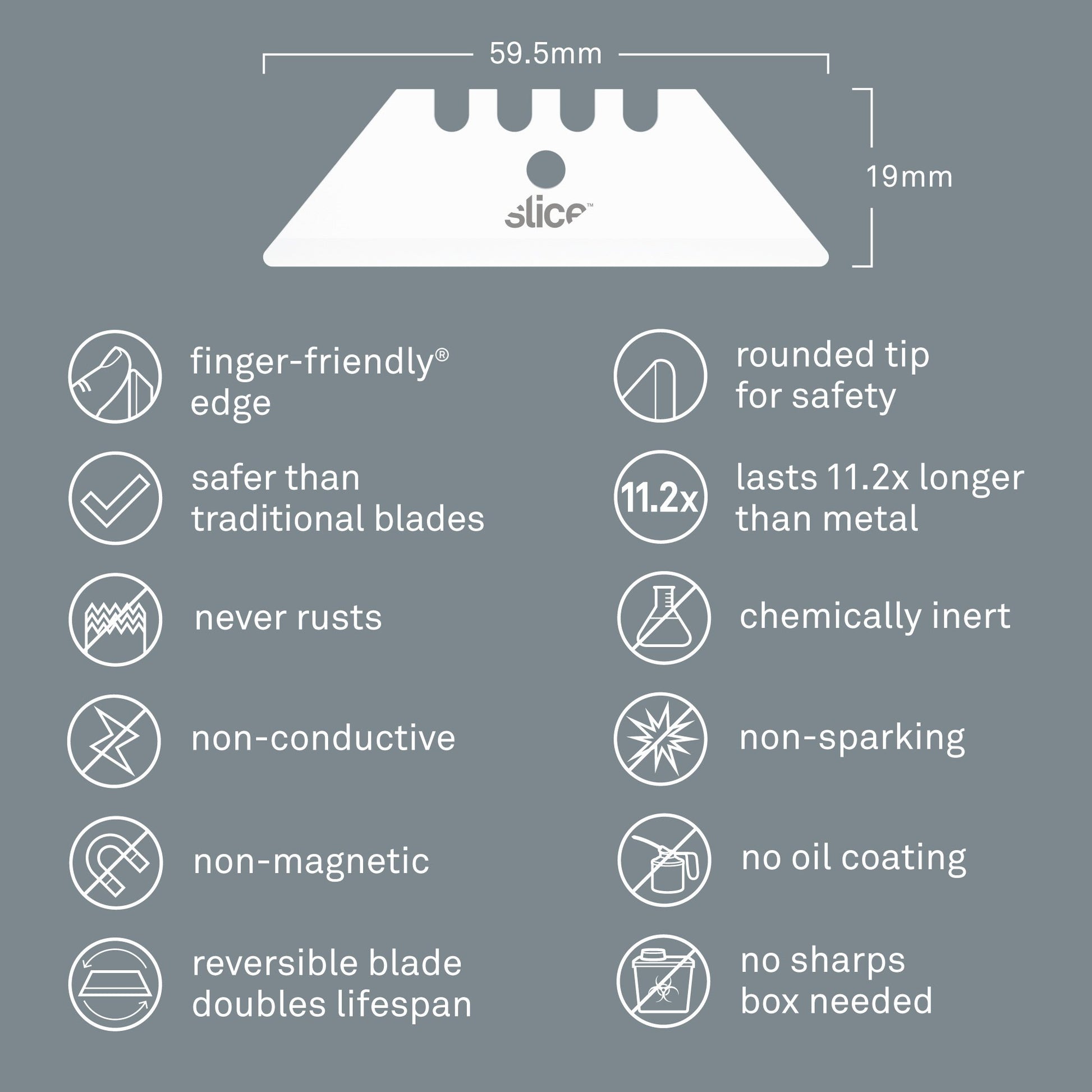

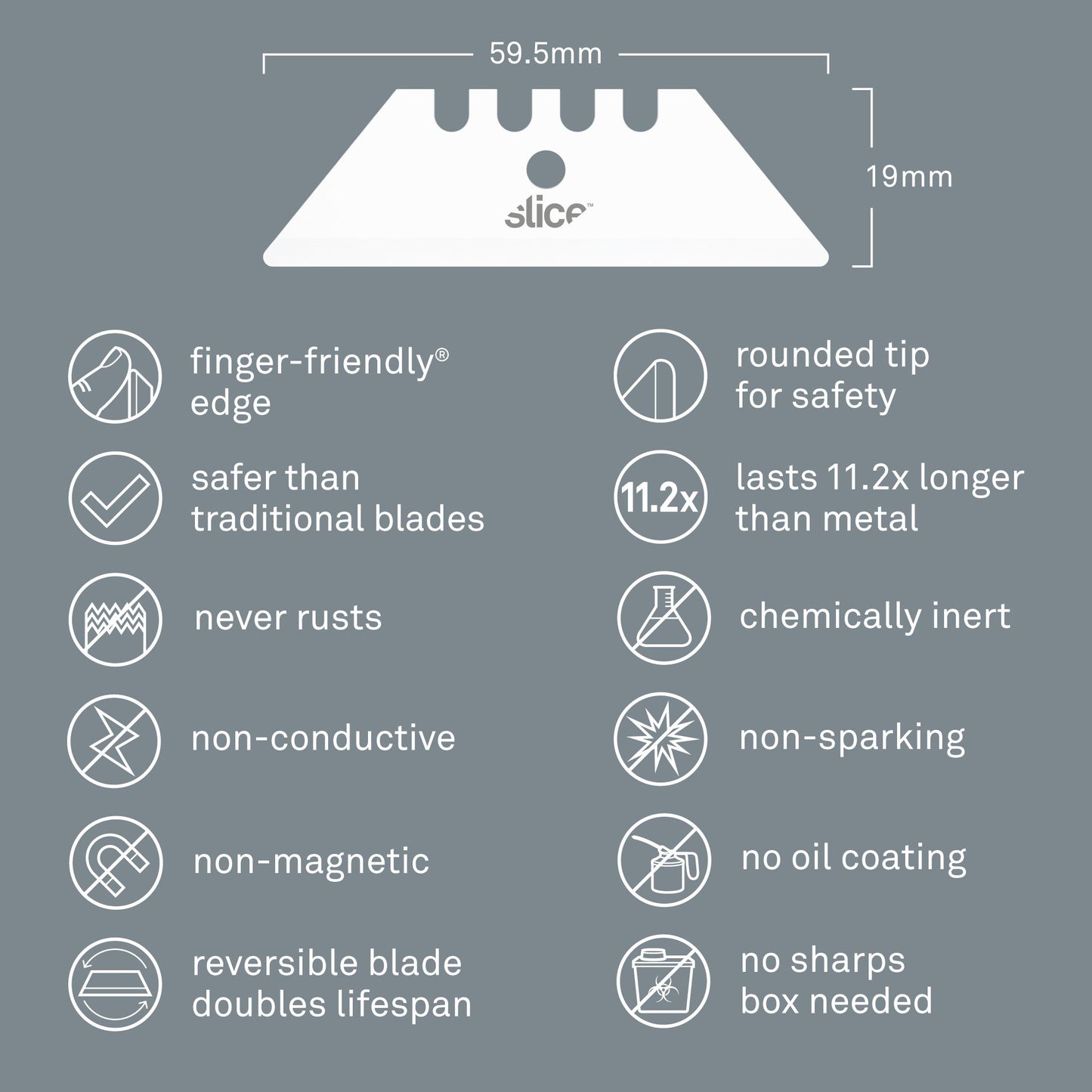

- 刀片类型: 圆弧形刀尖

- 比传统刀片更安全

- 独特安全刀刃,既安全又能利落地切割

- 使用寿命较钢制刀片长11倍

- 更换刀片次数越少 = 伤害越少

- 减少伤害,降低成本

- 无火花、不导电、无磁性

- 刀片为化学堕性材质,具不生锈特性

- 刀片无需上保养油,润滑油

- 不再需要刀片弃置盒

- 100%可回收再利用

- 刀片可承受从摄氏零下40度至1600度的温度

- 兼容刀款:10490, 10491, 10496, 10497, 10582, 10590, 10594

- 每组2片双面刀片

- SKU编号 #10524

Product Specifications

Product Specifications

Cutting Depth:

Material: zirconium oxide

Dimensions: L x W x H

Weight: 0.04 lbRelated Products

FAQ

What Can I Use Ceramic Utility Blades For?

Use these blades for the same applications as you would use a regular utility blade, and more. The properties of advanced ceramics ensure that your blade is non-sparking, chemically inert, autoclave-friendly, and never rusts.

Slice®’s thicker, more durable ceramic blades do not flex in the same way as metal, so they’re not ideal for any application that exerts a side load or requires the blade to bend. But typical uses, such as hand trimming solder from metal parts or plastic flash from injection-molded products are just as easy—and much safer—with Slice utility blades.

Slice®’s thicker, more durable ceramic blades do not flex in the same way as metal, so they’re not ideal for any application that exerts a side load or requires the blade to bend. But typical uses, such as hand trimming solder from metal parts or plastic flash from injection-molded products are just as easy—and much safer—with Slice utility blades.

What’s the Advantage of Ceramic Blades?

Until recently, utility blade types included only steel. The sole customizable option was to choose a different handle. Slice added ceramics to the market. Since then, other companies have started manufacturing ceramic utility blades, but none offer Slice’s finger-friendly® safety edge.

For that reason, the best utility blades to reduce hand and finger injuries are Slice blades. Our proprietary grind creates an edge that cuts materials effectively and is safe to the touch. Slice blades also hold their cutting edge, on average, 11.2 times longer than steel. This means fewer blade replacements and therefore fewer opportunities for injury.

Other advantages of advanced ceramics come from the properties of our ceramic material. Zirconium oxide is chemically inert, non-sparking and non-magnetic. It can be heated up to 1600 degrees Celsius and requires no special oil or lubricant coating to maintain sharpness.

For that reason, the best utility blades to reduce hand and finger injuries are Slice blades. Our proprietary grind creates an edge that cuts materials effectively and is safe to the touch. Slice blades also hold their cutting edge, on average, 11.2 times longer than steel. This means fewer blade replacements and therefore fewer opportunities for injury.

Other advantages of advanced ceramics come from the properties of our ceramic material. Zirconium oxide is chemically inert, non-sparking and non-magnetic. It can be heated up to 1600 degrees Celsius and requires no special oil or lubricant coating to maintain sharpness.

Does Slice Make a Ceramic Utility Knife?

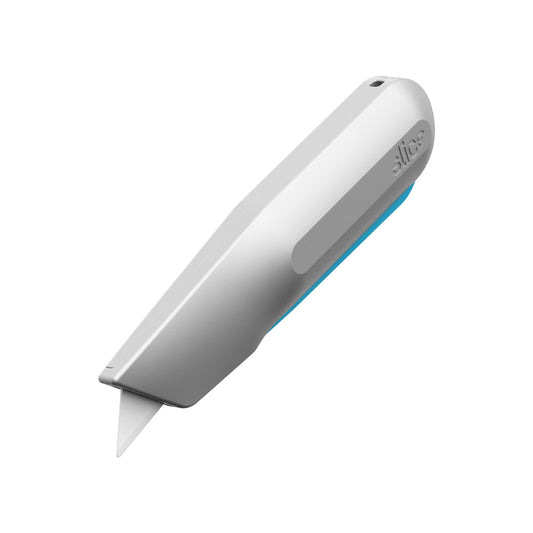

Yes! We make a whole line of utility knives with different blade retraction options, including manual retraction (with multiple fixed-position cutting depth options), auto-retractable, and smart-retracting handles. Each ceramic utility knife offers different choices to account for personal preferences and varying safety regulations.

What Handles Will This Utility Blade Fit?

The trapezoidal utility blades that Slice makes (that is, the 10523, 10524, 10525 series) are all compatible with our metal-handle utility knives. These knives include the 10490 Manual Metal-Handle Utility Knife and the 10491 Auto-Retractable Metal-Handle Utility Knife. Both these knives are ambidextrous and feature a large, sturdy handle. The manual version locks in place, offering three preset cutting depths, while the auto-retractable version retracts on its own, as soon as the user releases the slider.