工业安全美工刀

SKU #10559

Slice® 10559工业安全美工刀较一般刀片还要长3英寸(76mm),适合切割像是泡沫板、特别厚的瓦愣纸、棉絮及绝缘材料。其耐用手柄的5段式伸缩设计可为生产车间或个人工作室提供符合不同工作需求切割长度。提供切割长度如下:6mm、28mm、53mm及76mm。搭配了Slice独特的安全刀片,让您在能利落地切割同时保有较一般金属或陶瓷刀片还高的安全性。我们无需工具即可替换刀片的机制更让您可以轻易地变换刀片方向,切换成左手使用。Slice的安全刀片有着具化学堕性、无火花、无需上油保养及较不生锈的特性,其使用寿命更比钢制刀片还要长11倍。

- 安装刀片类型: 圆弧形刀尖

- 经久耐用的尼龙刀柄

- 手动4段式伸缩设计

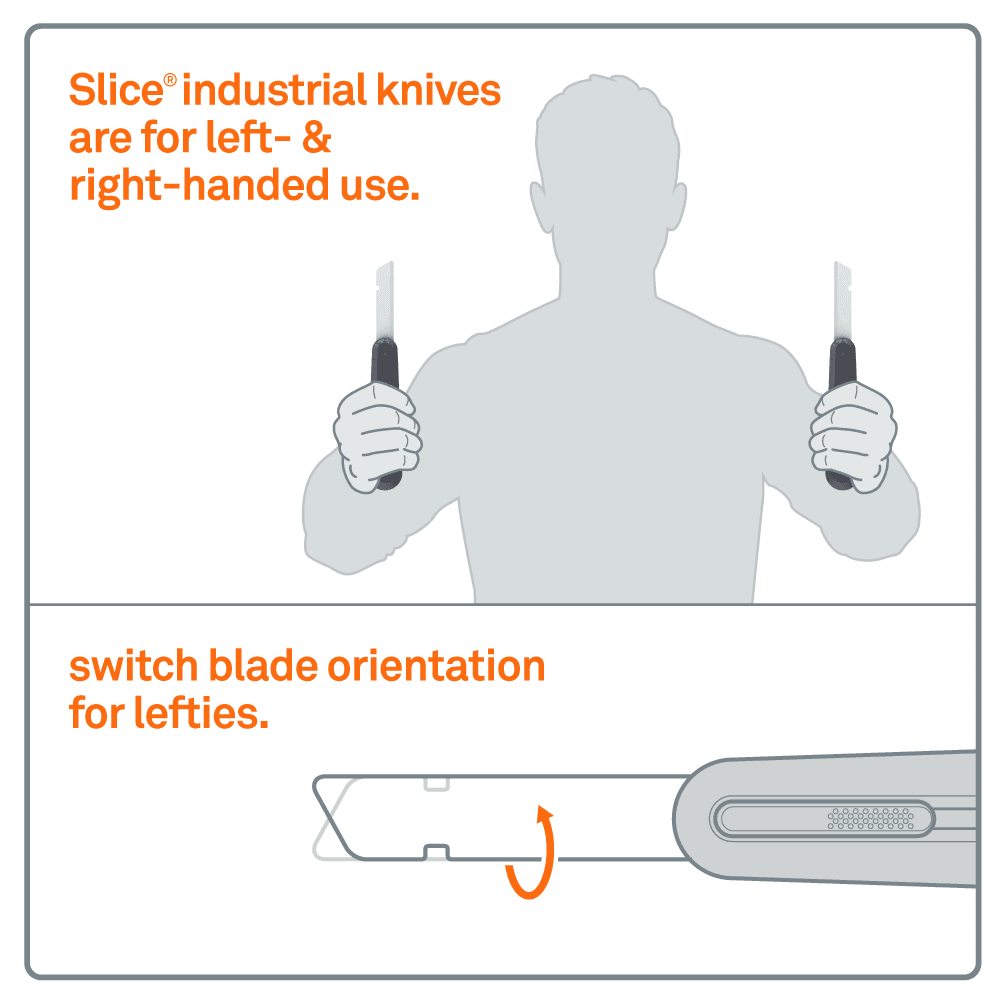

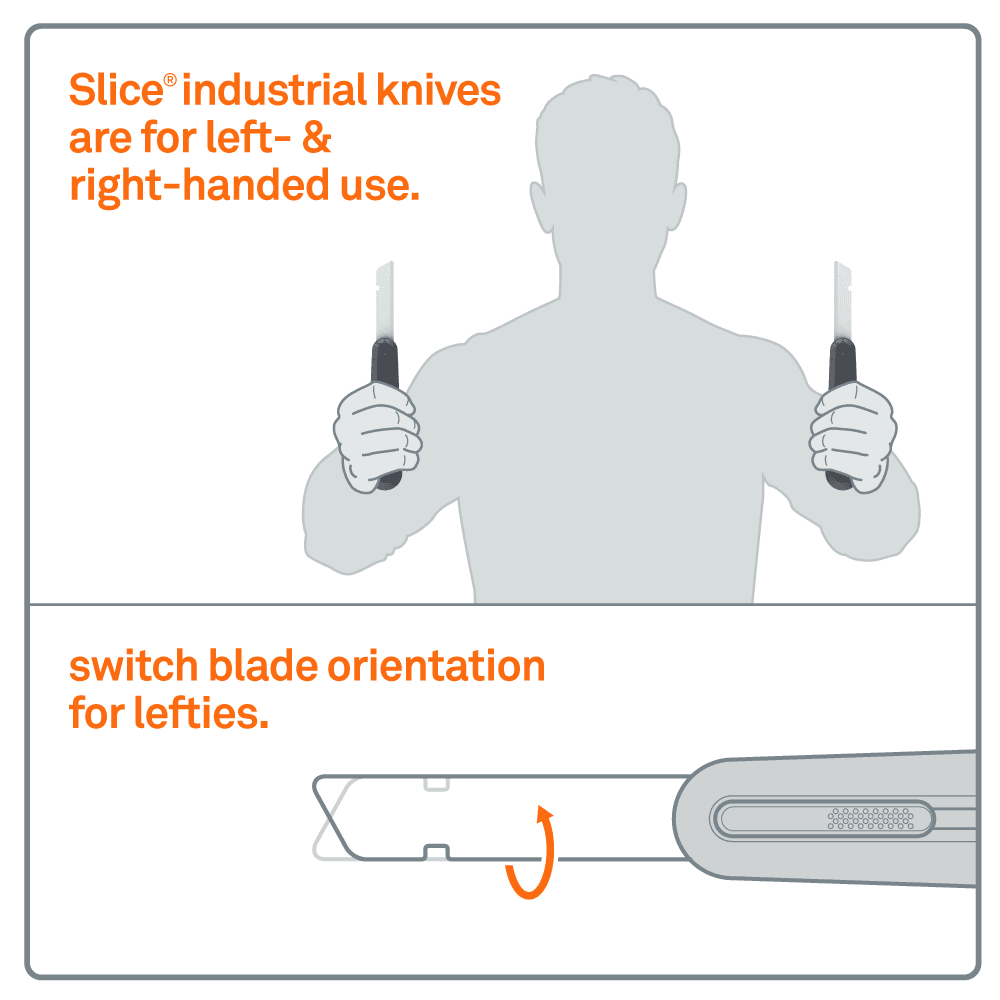

- 双手通用设计: 变换刀片方向即可让左撇子使用

- 采用独特的安全刀片,既安全又能利落地切割

- 减少伤害,降低成本

- 无火花、不导电、无磁性刀片

- 刀片为化学堕性材质,具不生锈特性

- 刀片无需上保养油,润滑油

- 100%纯氧化锆陶瓷制作

- 刀刃使用寿命较钢制刀刃长11.2倍

- 更换刀片次数越少 = 伤害越少

- 刀片可承受高达摄氏1600度高温

- 兼容刀片: 10538, 10539, 10540

- 更换刀片无需使用工具

- SKU编号 #10559

Great for:

- Cutting thick materials such as foam, batting, and fiberglass insulation

- Slicing ceiling tile

- Cutting ceramic fiber blanket

Product Specifications

Product Specifications

Cutting Depth:

Material: GFN, POM, stainless steel, carbon steel, zirconium oxide

Dimensions: L x W x H

Weight: 0.22 lb

What Customers Are Saying

-

This tool is amazing! For years I have used a box cutter or long steel insulation knife; NO MORE! This cuts through insulation super clean and quick. The blade also does not present a cutting hazard to your hands as well! This knife is the greatest!

This tool is amazing! For years I have used a box cutter or long steel insulation knife; NO MORE! This cuts through insulation super clean and quick. The blade also does not present a cutting hazard to your hands as well! This knife is the greatest!

Lynne Brower

-

Cut through the insulation like butter, perfect for that of job! I could make precise cuts too. Great thanks!

Cut through the insulation like butter, perfect for that of job! I could make precise cuts too. Great thanks!

michael updike

-

This knife made the job much easier. Tried other regular knives, even more expensive ones sold at local hardware stores. The Slice knife is in a class by itself. I liked that it was a safe blade that cut through insulation without drag or gumming up. Great purchase!

This knife made the job much easier. Tried other regular knives, even more expensive ones sold at local hardware stores. The Slice knife is in a class by itself. I liked that it was a safe blade that cut through insulation without drag or gumming up. Great purchase!

ASM_JoeV

Videos

-

Manual Industrial Knife

-

Blade Replacement for Slice Industrial Knives

-

Cutting Fiberglass Insulation With Safe, Durable Tools

-

How to Cut Ceiling Tile: Safety First

-

How to Cut Ceramic Fiber Blanket With Slice

-

How to Cut Foam: Slice® Safety Blades vs. Traditional Blades

Compatible Products

Related Products

FAQ

What Are Industrial Knives?

An industrial knife is any knife designed for use in an industrial setting. More specifically, some cutting applications are much more common in manufacturing or industrial workplaces. While it’s certainly possible to use these tools around the home, it happens less frequently. Of course, the tool you use depends on what you need it to do, and many home workshops or craft rooms contain specialized tools.

Are These the Only Knives You Make for Industrial Use?

In a sense, all our knives are industrial knives because they were designed for—and often in conjunction with—industrial customers, to meet their needs. The term ‘industrial’ also implies a certain level of durability, since industrial settings require constant tool use over long periods of time. We use sturdy materials such as reinforced (glass-filled) nylon for our handles. One of our customers even submitted a video of him running over our box cutter with a forklift, and not leaving a scratch.

The Slice® box cutters were originally designed to cut 98 percent of the corrugated on the market (double-walled corrugated). When manufacturers asked for a longer blade to deal with triple-walled corrugated and other, thicker, materials, we introduced our line of utility knives. Some manufacturers, especially those dealing with thick industrial foam components or insulation, needed an even longer blade, which is why we introduced our 10559 and 10560 knives.

The Slice® box cutters were originally designed to cut 98 percent of the corrugated on the market (double-walled corrugated). When manufacturers asked for a longer blade to deal with triple-walled corrugated and other, thicker, materials, we introduced our line of utility knives. Some manufacturers, especially those dealing with thick industrial foam components or insulation, needed an even longer blade, which is why we introduced our 10559 and 10560 knives.

What Makes the Slice Industrial Cutting Blades Different?

Typical industrial knives and blades feature dangerously over-sharpened metal blades. Because metal is a soft material, it dulls quickly. Blade manufacturers sharpen metal excessively in order to compensate for its quick dulling and extend the lifespan of the product. Unfortunately, most ceramic blade manufacturers also use this level of sharpness, simply because it’s what people have come to expect.

Slice reexamined advanced ceramics and the definition of effective sharpness and created a proprietary grind that results in a finger-friendly® blade. All our blades stand out from their competitors—metal and ceramic—because of our safety grind, which cuts materials effectively but is safer to touch.

Slice reexamined advanced ceramics and the definition of effective sharpness and created a proprietary grind that results in a finger-friendly® blade. All our blades stand out from their competitors—metal and ceramic—because of our safety grind, which cuts materials effectively but is safer to touch.

What Materials Can I Cut With Slice Industrial Knives?

Slice industrial cutting blades were designed specifically to cut industrial foam used in manufacturing, but can handle any material that requires a longer blade. General safety principles suggest using the shortest possible blade for the job, so if you never really need more than an inch of exposed blade, we recommend that you look at our utility knives or box cutters. But if an extra-long blade is sometimes required, the 10559 and 10560 are your best bet. Keep in mind that if you prefer one tool, the 10559 Manual Industrial Knife has four preset exposed-blade positions, so you aren’t required to fully extend the blade for every cut.

Which Slice Blade Should I Choose?

The 10559 and 10560 come with installed rounded-tip industrial cutting blades because safety managers prefer the extra protection against punctures. Most materials don’t need a pointed tip, so it makes sense to try the installed 10538 blade first. If you find, however, that you need a pointed tip to initiate the cut in your material, the 10539 blade will be the best choice. We’re also releasing the 10540 serrated industrial blade for any applications that require sawing with your Slice industrial knife.