Translation missing: sv.accessibility.faq_content_title

What Is a Utility Knife?

Utility knives are hand tools that cut corrugated packaging, plastic, and other materials. Commonly used for both household and industrial applications, the best utility knives feature safety measures—such as patent-pending finger-friendly® Slice® blades—to prevent lacerations. Lacerations are a major cause of injuries in the workplace and elsewhere, but they’re largely preventable.

Some utility knives allow you to choose different fixed-length blade positions to match the depth of the material you're cutting, while others have auto-retracting blades, which prevent accidents when the tool is not in use. Still others fold to protect the blade.

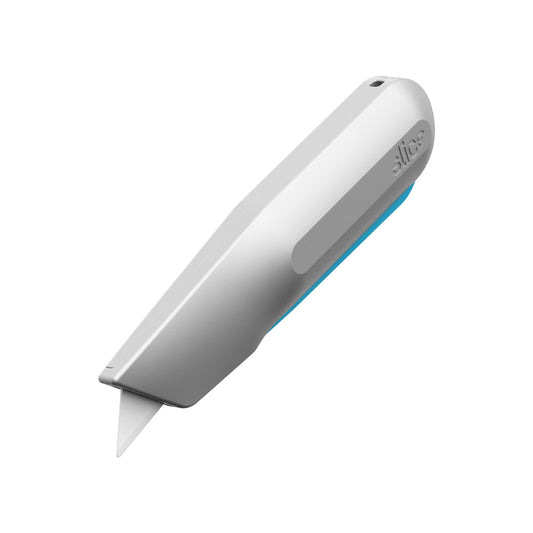

Most Slice utility knives offer both manual- and auto-retraction models. Our 10562 Folding Utility Knife folds to protect the blade. We also offer the innovative 10558 Smart-Retracting Utility Knife: the blade retracts as soon as it loses contact with the material you’re cutting. All Slice manual tools feature multiple blade position settings, and Slice auto-retraction models include well-established blade-retraction technology.

Some utility knives allow you to choose different fixed-length blade positions to match the depth of the material you're cutting, while others have auto-retracting blades, which prevent accidents when the tool is not in use. Still others fold to protect the blade.

Most Slice utility knives offer both manual- and auto-retraction models. Our 10562 Folding Utility Knife folds to protect the blade. We also offer the innovative 10558 Smart-Retracting Utility Knife: the blade retracts as soon as it loses contact with the material you’re cutting. All Slice manual tools feature multiple blade position settings, and Slice auto-retraction models include well-established blade-retraction technology.

What Is a Utility Knife Used For?

Industrial utility knife uses include opening and breaking down corrugated boxes, cutting pallet wrap and banding, trimming flash from plastic components, and cutting raw materials to shape on the factory floor. As the name implies, these are tough, general-purpose, multi-use tools.

All Slice blades are made of zirconium oxide, which is chemically inert and therefore never rusts. It also has high temperature tolerances: it remains structurally sound from -40 degrees to 1600 degrees, Celsius. Because of this, 100 percent zirconium oxide blades are an excellent option for labs or extreme environments.

All Slice blades are made of zirconium oxide, which is chemically inert and therefore never rusts. It also has high temperature tolerances: it remains structurally sound from -40 degrees to 1600 degrees, Celsius. Because of this, 100 percent zirconium oxide blades are an excellent option for labs or extreme environments.

Are Utility Knives and Box Cutters the Same?

All Slice utility knives and box cutters use our unique safety blades and include many of the same features, but they offer a variety of handle designs and blade lengths.

The shorter blade of a box cutter knife, like the Slice Auto-Retractable Box Cutter, the Manual Pen Cutter, or the Manual Mini Cutter, easily opens packing materials while minimizing blade exposure. This reduces the risk of an accident or damage to the box's contents.

A Slice utility knife, whether it’s one of our glass-filled-nylon-handle utility knives or metal-handle utility knives, has a longer blade and can cut a broader range of materials. For even deeper cuts, Slice offers industrial knives, with extra-long blades. They’re well suited to cutting soft, thick materials like foam or fiberglass insulation.

The best utility knife or box cutter for any job is the one that’s safest and that makes a clean cut in one pass with the smallest amount of blade exposure.

The shorter blade of a box cutter knife, like the Slice Auto-Retractable Box Cutter, the Manual Pen Cutter, or the Manual Mini Cutter, easily opens packing materials while minimizing blade exposure. This reduces the risk of an accident or damage to the box's contents.

A Slice utility knife, whether it’s one of our glass-filled-nylon-handle utility knives or metal-handle utility knives, has a longer blade and can cut a broader range of materials. For even deeper cuts, Slice offers industrial knives, with extra-long blades. They’re well suited to cutting soft, thick materials like foam or fiberglass insulation.

The best utility knife or box cutter for any job is the one that’s safest and that makes a clean cut in one pass with the smallest amount of blade exposure.

What Sets Slice Utility Tools Apart?

All Slice blades are made of 100 percent zirconium oxide, an advanced ceramic that’s rustproof, non-conductive, anti-magnetic, and won't spark. Slice applies its patent-pending finger-friendly edge grind to this material. This creates a blade that effectively cuts materials but is safe enough to touch.

Steel blades are dangerously sharp out of the box because steel dulls relatively quickly. Blades are most dangerous when they’re too sharp or too dull. A too-sharp blade easily penetrates skin. With a dull blade, the user must apply extra pressure, which increases the chances of the tool slipping uncontrollably.

Zirconium oxide is extremely hard and, with the Slice proprietary design, our blades last up to 11 times longer than steel. This means that tools like the Slice 10554 Auto-Retractable Utility Knife or the 10490 Manual Metal-Handle Utility Knife provide an effective and consistent cutting edge that outlasts comparable steel-bladed knives. Fewer blade replacements and a reversible (double-edged) blade significantly reduce maintenance costs.

Traditional ceramic blade manufacturers mimic the dangerously sharp design popularized by metal blades, and therefore cause lacerations just as easily. As far as the benefits of ceramics, not all ceramic blades feature the same material composition, so performance may differ from manufacturer to manufacturer.

Steel blades are dangerously sharp out of the box because steel dulls relatively quickly. Blades are most dangerous when they’re too sharp or too dull. A too-sharp blade easily penetrates skin. With a dull blade, the user must apply extra pressure, which increases the chances of the tool slipping uncontrollably.

Zirconium oxide is extremely hard and, with the Slice proprietary design, our blades last up to 11 times longer than steel. This means that tools like the Slice 10554 Auto-Retractable Utility Knife or the 10490 Manual Metal-Handle Utility Knife provide an effective and consistent cutting edge that outlasts comparable steel-bladed knives. Fewer blade replacements and a reversible (double-edged) blade significantly reduce maintenance costs.

Traditional ceramic blade manufacturers mimic the dangerously sharp design popularized by metal blades, and therefore cause lacerations just as easily. As far as the benefits of ceramics, not all ceramic blades feature the same material composition, so performance may differ from manufacturer to manufacturer.

Slice Utility Knife Blade Options

The tools featured on this page ship with a double-edged, rounded-tip blade, and are compatible with pointed-tip replacement blades.

Additionally, Slice makes serrated replacement blades for the metal-handle utility knives (10490 and 10491) and the industrial knives (10559 and 10560).

The blade you choose depends on how you’ll use the tool. Rounded-tip blades protect from accidental punctures and can handle most materials. Pointed-tip blades are necessary when you need to puncture your material to initiate the cut. And a serrated blade works best for jobs that require a sawing motion.

Slice pen cutters, mini cutters, and box cutters all use the same box cutter blades. Our Folding Utility Knife and glass-filled-nylon utility knives share the utility knife blades. The industrial knives have their own blade models (Industrial Blades), as do the metal-handle utility knives, which take the familiar trapezoidal utility blades.

Additionally, Slice makes serrated replacement blades for the metal-handle utility knives (10490 and 10491) and the industrial knives (10559 and 10560).

The blade you choose depends on how you’ll use the tool. Rounded-tip blades protect from accidental punctures and can handle most materials. Pointed-tip blades are necessary when you need to puncture your material to initiate the cut. And a serrated blade works best for jobs that require a sawing motion.

Slice pen cutters, mini cutters, and box cutters all use the same box cutter blades. Our Folding Utility Knife and glass-filled-nylon utility knives share the utility knife blades. The industrial knives have their own blade models (Industrial Blades), as do the metal-handle utility knives, which take the familiar trapezoidal utility blades.

Handles Designed for Durability, Safety, and Convenience

Slice utility knives and box cutters have handles made of either metal or sturdy glass-filled nylon (GFN), so they’re suited to heavy use.

The Slice box cutters have a J-hook handle that hooks on pockets, keeping the blade away from the body. The mini cutters, box cutters, GFN-handle utility knives, and pen cutters feature a lanyard hole so you can easily store your utility knife when it's not in use. The Slice mini cutter handles are also magnetized, providing another way to keep them within easy reach. The folding knife features a handy belt clip.

All Slice utility knives are adaptable for left- or right-handed use.

The Slice box cutters have a J-hook handle that hooks on pockets, keeping the blade away from the body. The mini cutters, box cutters, GFN-handle utility knives, and pen cutters feature a lanyard hole so you can easily store your utility knife when it's not in use. The Slice mini cutter handles are also magnetized, providing another way to keep them within easy reach. The folding knife features a handy belt clip.

All Slice utility knives are adaptable for left- or right-handed use.

What Blade Control Options Do Slice Utility Knives Have?

These tools feature several types of blade controls: manual retraction, auto-retraction, and smart retraction. The folding knife, of course, folds to store the blade. Products like the Slice Manual Industrial Knife have a slider that adjusts the blade into one of several positions, while the Auto-Retractable Pen Cutter is a retractable utility knife: the blade retracts when the user releases the slider button. The Slice 10558 Smart-Retracting Utility Knife has an innovative feature that retracts the blade if it loses contact with the cutting material, even when the user's hand is still on the slider. This prevents injuries if the tool slips.

What Does Ergo-Pull Mean?

Slice’s Ergo-Pull™ technology was introduced with the 10558 Utility Knife. While reevaluating every aspect of design, we looked at the ergonomic impact of the slider used to unsheath the blade in typical blade retraction mechanisms. What we discovered is that, while most sliders require a push action to activate the blade, a pull action is in fact more ergonomic.

Think of it this way: you’re already pulling the tool towards you during the cut, so pushing the slider down at the same time creates tension in your hand. Pulling the slider instead is a more natural action. Going a step further, the position of the slider, when engaged, results in a solid, balanced grip with less rotational hand strain. Traditional designs require the user to rotate their hand awkwardly.

To test the effectiveness of our new idea, Slice hired US Ergonomics in September 2016 to run comparisons between the 10558 tool and a typical (non-Slice) push-slider knife. Their conclusion?

“The Slice [Ergo Pull] resulted in lower forearm and hand muscle effort than the standard push blade lever utility knife.“

For more details on our ergonomic testing, check out the FAQ: How Do I Know Slice Tools Are More Ergonomic?

Think of it this way: you’re already pulling the tool towards you during the cut, so pushing the slider down at the same time creates tension in your hand. Pulling the slider instead is a more natural action. Going a step further, the position of the slider, when engaged, results in a solid, balanced grip with less rotational hand strain. Traditional designs require the user to rotate their hand awkwardly.

To test the effectiveness of our new idea, Slice hired US Ergonomics in September 2016 to run comparisons between the 10558 tool and a typical (non-Slice) push-slider knife. Their conclusion?

“The Slice [Ergo Pull] resulted in lower forearm and hand muscle effort than the standard push blade lever utility knife.“

For more details on our ergonomic testing, check out the FAQ: How Do I Know Slice Tools Are More Ergonomic?

What If I Need to Do Detailed Work in a Small Space?

Slice makes a variety of handles because we know there are a variety of applications and personal preferences out there. We encourage customers to find the best Slice tool for the job. Some specialty applications require the strength of a utility knife, but take place in a narrow space, or need more control than a typical everyday knife can offer.

If you have jobs that require slimmer cutting tools to perform more detailed work, head over to the Precision Knives category. These tools offer a higher degree of control and a smaller handle profile. Their blades are smaller than those profiled here, but they are still made of extremely hard advanced ceramics and have all the same benefits. If you need a handle that’s thinner still, consider our Ceramic Scalpels. These are excellent for delicate jobs in awkward spaces, while beefier utility knives excel at tougher general-purpose tasks.

If you have jobs that require slimmer cutting tools to perform more detailed work, head over to the Precision Knives category. These tools offer a higher degree of control and a smaller handle profile. Their blades are smaller than those profiled here, but they are still made of extremely hard advanced ceramics and have all the same benefits. If you need a handle that’s thinner still, consider our Ceramic Scalpels. These are excellent for delicate jobs in awkward spaces, while beefier utility knives excel at tougher general-purpose tasks.